I’ve finally got round to finish the

Scalescenes R012a Jack Arch Bridge. I didn’t have much to do to finish it, and

i got it finished in no time at all. It’s just taken me awhile to get round to

write the post. I feel frustrated with the new format of the blog writing

program which I use. So what used to be an easy enjoyable task to write a post,

has now become slow and frustrating. I suppose I’ll get my head around it

eventually, but for now, I’ll just have to suffer the complications of the new

system. Apologies for the layout.

Right, here we go.

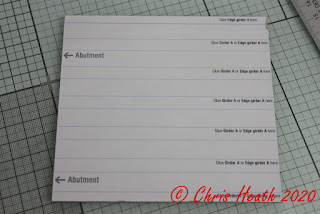

Next to be made are the abutments. Like with the main deck, there is a very clever grid system, to make

sure that everything is kept true and square.

It also helps with the height calculations for your bridge. Cut out the

two abutments.

I’ve gone for 15’ 6” or 4.7m.

Next cut two of the abutment wall b pieces, and glue to the back of the

abutment walls.

I’ll show you what I retrieved from the recycling bin at work. These

two, very heavy and compact batteries out of a portable power supply, have made

their way to my work table, and they prove very effective as weights to make sure

good adhesion to glued up components. Result!!

Next cut out and glue together the buttresses into blocks of four.

Once the glue has set, glue the Buttresses to the back of the main

abutment. Clamp these together and leave to dry.

Next cut out the abutment wall cover layer. I love the fine detail of

this brickwork. The water staining is so realistic.

Wrap and glue the cover layer around the base

layer.Top tip. When i built the previous version of this kit, the girder

bridge, when came to glue the wing walls to the abutment, because I use self

adhesive labels, the wing walls have eventually worked the cover layer lose. So

this time I’ve glued the cove layer to the abutment to make sure it stays in

place.

Next comes the buttress cover layers. Take care to use a new sharp fine blade

to cut out the individual bricks. I like to run a marker along the raw edge of

the brick. So that when wrapped around the buttress, it disguises the join.

So that when wrapped around the buttress, it disguises the join. Next cut out the abutment copping and glue into place.

Buttress capping next. Cut out the base layers and wrap the cover layers

over them.

The glue to the top of the buttresses. That completes the abutment

walls.

Next comes the wing walls. Firstly,cut and glue the wing wall buttress

base layers into three.

Wrap with the cover layer.

Fit the capping and set aside.

Next cut out the wing wall coping base layers and wrap the cover layers

around.

The wing wall are next. Cut out both the front and back pieces.

Then glue the back to back. Set aside for the glue to dry.

Once the glue has dried, take a new sharp blade and using a steel ruler,

run along the light blue line at an angle of 45 degrees.

Fit the coping to the top of the wing wall. Trim the coping to the size of the wing wall.

Glue the wing wall to the abutment. This is where the extra gluing comes into play.

Fit the wing wall buttresses next.

And that’s it. I hope that this build has helped with original question about how to

make the Jack Arch. (I know that the copyright date is wrong. I had to edit the last of the pictures in a different editing program).

· Until Next Time.............