Well it’s

been a while. I apologise for being away for so long, but what with work

commitments and life in general, along with the loss of my mojo, posting on my

blog was the last thing on my mind. But now I’m back with renewed enthusiasm

and drive!

I’m eagerly awaiting the release of

the new Shops on a slope kit from Scalescenes. Hopefully this will be in the

next few weeks, but until then, I’ve got my hands on the free giveaway in the

September issue of Hornby Magazine.

It’s a Low Relief Corner Shop, and I

can’t wait to get my teeth into it.

Please forgive me for the layout of

this post, but the version of the blog publisher I use has changed immensely,

and I’m try to work my way around the changes.

So here goes, let’s see if I can

remember how to do these kits.

It all starts with the ingenious way that the drainpipe is incorporated within the interior walls. There’s no way it can be knocked off once finished.

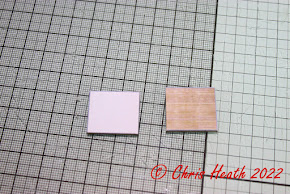

Next cut out

all of the floors and ceilings and glue the corresponding pieces back to back

with each other.

Next, cut

out and glue back to back, the two side walls. Once dry, fit into place. Cut

out the upper ceiling and glue in place.

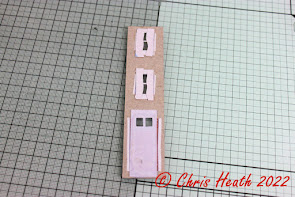

Next, cut

out the smaller of the front wall base layer and cover layer. A couple of top

tips at this stage. With a felt pen or marker, try and match the colour of the

brick and mark the underside of the window openings, on both the base layer and

cover layer. This hides the raw edge of the cover layer and the base layer. The

next top tip, just cut out the header and sill openings on the cover layer

leaving the flaps uncut at this stage. I find that leaving them uncut, it helps

to keep the cover layer square when gluing to the base layer. Cut the window

openings out once the cover layer is glued to the base layer.

Next, cut

out and glue the sills into place.

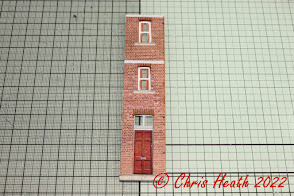

Windows are

next. I’m fortunate that I have supply of Scaleglaze windows, which are

brilliant, and I highly recommend them. They save so much time and effort in

cutting out fiddly windows, so I’ve used them, but if you haven’t got

Scaleglaze windows, carefully cut out the windows supplied with the kit and

glue into place along with the door. At this point, if you are putting curtains

on, do it now. Once complete, glue into position.

The shop

floor is next. Simply cut out and glue into position. Once the floor is in

position, add the interior detail of the shop.

The main

front wall is next, and it’s just repeat as for the small wall. Apart from you

need to introduce an angle in the base layer before you glue the cover layer in

place. Once complete, and if you’ve fit any interior detail, fit and glue into

position.

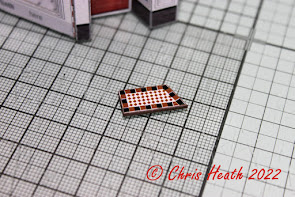

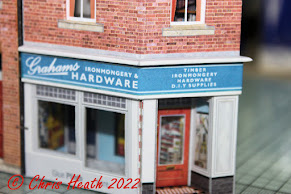

Next,

carefully cut out the shop overlay and mount onto clear film or acetate, then

glue into position on the shop front.

The

Shopfront 2 is next. Carefully cut out and mount onto acetate as before and

carefully score the red score lines, and fold into the correct angles. Glue

into place and the fit the door shop step into position.

Working on

the shop front is next. Cut out, score and fit the first fascia base layer and

glue into place. Next cut out both the base and cover layers for the fascia ledge and glue together. Once dry, carefully cut out the hatched area and glue

over the fascia. Cut out and glue into position the fascia cover layer. Then cut

out and fit your choice of shop sign.

Cut out and

fit the shop overlay into place.

Cut out both

the plinth base and cover layer and glue together. Touch up any raw edges with

a marker pen, then glue into position.

Cut out,

colour the raw edges, test fit and glue the front wall ledges into position.

The gutter

is next. Cut out the base layer and glue the corresponding cover layers into

position. Touch up any raw edges, then test fit and glue into position.

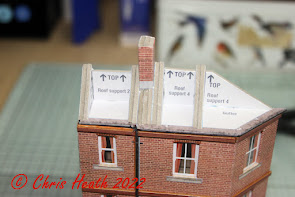

The roof

supports and chimney are next. Glue the three chimney base layers together.

While the glue sets, cut out the chimney cover layer. Once dried, wrap around

the base layer. Cut out and glue together into blocks of two, both of the roof

supports. Then glue onto the corresponding positions on the gutter layer. Clamp

together to make sure they set.

Cut out all

of the roof supports and glue together roof supports 1 and 3 into blocks of

two. Once dried, again following the blue guidelines, fit to the gutter

layer.

Top tip. Make

sure that all of the supports are in line. This will make sure that the roof is

nice and flat.

The roof

comes next. Cut out the roof base layers and carefully score the red line on

the larger piece. Cut out the individual tiles for both the roof sections. Take

note that the tile strips and the base layers, now come with numbered

references. These help with lining up the weathering patterns on the tiles.

Continue to apply the tile strips all the way to the top.

Once you’ve

completed the tiles, test fit and glue into position the roof sections and fit

the ridge tiles.

Cut out the

chimney capping base and cover with the cover layer. Fit into place.

And finally,

cut out and glue into position the side wall overlay.

And that’s

it. I’m calling this done. I’ve enjoyed this kit and it’s good to get back into

the swing of blogging about the process. Hopefully the main kit that I think

that this kit is taken from, the Low Relief Shops on a Slope, isn’t too long

before it’s released. Can’t wait. It’s been a long time coming.

Until Next Time……………..